Applications & Benefits

Main applications

Merchant Navy vessels: any main & auxiliary marine diesel engine

Diesel Engine Power Plans

MARPOL Compliant Exhaust Emissions

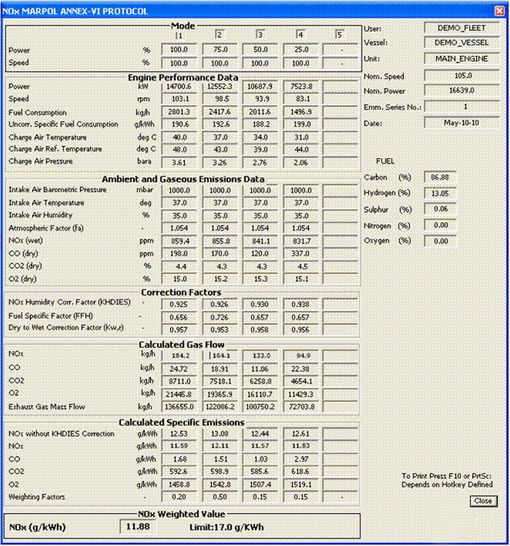

MARPOL compliant specific NOx emissions in g/kWh “Direct monitoring method” as alternative to the “Onboard Verification Procedure” “Simplified Measurement Method” to prove compliance with MARPOL limits after Modifications.

Engine optimization (FOC optimized)

Additional flexibility regarding spare parts and settings

Knowledge of the actual NOX-Emissions and margin to the TIER Limits qualification for possible action

Verify compliance to MARPOL anywhere, anytime.

Verify compliance to national and local authorities also (Norway, Sweden, etc.) as well as for upcoming regulations.

SOx

Identify S-Content of fuel by CO2/SO2 ratio acc. to MEPC.184(59)

Adjusting cylinder lub-oil supply acc. to S-content of fuel

Applying the Guidelines for Exhaust Gas Cleaning Systems MEPC.184(59)

-Scheme A using Parameter and Emission Checks

-Scheme B Using Continuous Monitoring of SOX Emissions.

CO2

Accurate knowledge of the absolute CO2 emission as basis for a potential emission trading system, as well as improved efficiency and therefore reduced CO2 emissions.

Comparison for M/E measured CO2 total emissions against the corresponding values at the reference engine state i. e. the official shop tests and sea trials:

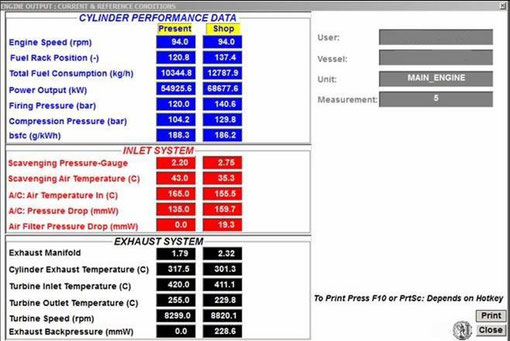

Power Measurement and Performance

No additional Hardware and sensors needed

One system for all engines (two- and four stroke)

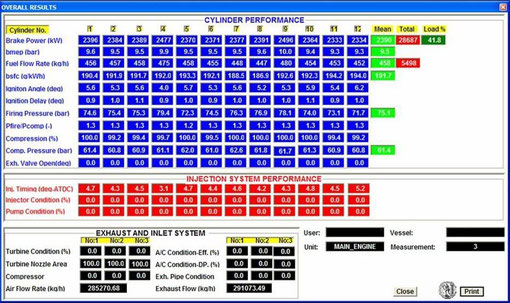

Power output of individual cylinder for main and aux-engines

Needed for specific exhaust gas emissions in g/kWh

Checking installed sensors condition (strain gauges, etc.)

Fuel Oil Consumption

Fuel oil consumption of individual cylinder for main and aux-engines

Checking installed fuel oil flowmeters aboard

Needed for specific exhaust gas emissions in g/kWh

No additional Hardware, no sensors

One system for all engines (two- and four stroke)

High Performance Engine Diagnosis

Further potential to save fuel

Condition control of engine, cylinder and subsystems

Additional information by determination of SOI, injection timing and the consumption of each single cylinder

Early recognition of failures

Arrange optimization measures from the Head-Office

Long term investigations and trend

Compare easily actual engine performance data with data from FAT

And a lot more…

Newbuildings

Definition of engine reference condition, for future use

Check engine settings (compared to shop tests) and define a reference for SOI abd VIT system function

Evaluate engine load curve, propeller margin and check shipyard data for power & fuel consumption during speed test etc

Investigate operation at low speed (slow steaming concept)

Cross check engine functions (as well as fuel consumption) and settings during sea trials

Check engine tuning compared to shop tests

From system measurement results derive a correlation for vessel fuel consumption vs cruising speed in tn/day and tn/mile. This correlation is very simple and can be used for chartering of vessel

etc

Utilize the system's simulator for investigation of problems (i.e.T/C Cutout investigation) in a very economic way

Conclusion

The 365 EMDS system provides detailed information concerning emissions and basic engine operation information. The main output values are summarized as follows:

- Exhaust gas mass flow rate.

- Exhaust gas O2 concentration.

- Engine NOx file.

- Engine shop tests and sea trials file.

- Measured emission concentrations.

- NOx in g/kWh as foreseen in MARPOL Annex VI

- Total and specific values for O2, CO, CO2 and SO2 (optional).

- Engine NOx protocol.

- Emission graphs.

- Raw cylinder pressure data.

- Peak compression pressure.

- Peak firing pressure.

- Pressure crank angle diagrams.

- Power output.

- Fuel consumption.

- Accurate engine speed

Fuel optimized engine mode

To save fuel and CO2 in international waters, simplified measurements or monitoring aboard might show to the Administration, that the adjusted engine (e.g. injection timing) is within the applicable emission limits.

NOX optimized engine mode

Allows to switch the engine into emission mode in special areas like ECAS or territorial waters with special regulations (e.g. Norway).

Green Image

Exhaust gas monitoring demonstrates ecology focus of the shipping company / operator to the public.

Flexibility in respect to upcoming regulations

A mobile measurement device for simplified measurements aboard or an installed and approved monitoring system allows the operator to adopt vessels operating to upcoming regulations.

More flexibility in respect to engine settings

Allows the operator to adjust engine settings and show compliance with appropriate emission limits to Authorities and authorized Organizations by simplified measurements aboard.

Ready for the future

When IMO MARPOL Tier III comes into force, a catalyst might be essential to be compliant with the emission limits. A monitoring system is then required for UREA Injection.

Power and FOC Measurement

Recheck installed sensors if any or determine the actual P and FOC of each single cylinder and the engine.

Detailed Engine Diagnosis

Detailed Diagnosis with the 365 EMDS enables engine checking, recognition of malfunctions and engine optimization. Ability to email the results to the head office gives you a perfect condition monitoring system.

Monitor and or verify the effect and efficiency indexes

All vessel owners and operators, of old and new ships, will be required to maintain a Ship Energy Efficiency Management Plan (SEEMP), which incorporates best practices for the fuel efficient operation of ships, such as better speed management throughout a ship’s voyage and the introduction of both newbuild and retro fit energy efficiency technologies. Efficiency measures can significantly reduce fuel consumption and, consequently, CO2 emissions.

There are thoughts in shipping across the globe, to implement and use efficiency data in a revolutionary way, and clean technologies and measures to be financed in the way contracts are written-up. Ship Owners and Operators should encourage efficiency to be factored into contracts between charterers, and between operators and ports, to encourage investment in money-saving efficiency technologies which will better their operations and business.

Finally

Become a more trusted and responsible partner.

Utilize technological innovations, that will lead to a step-change in operational efficiency.

Stay ahead of regulation.